Physicist hopes to build cheap 3D printer

- Ngoc Huynh

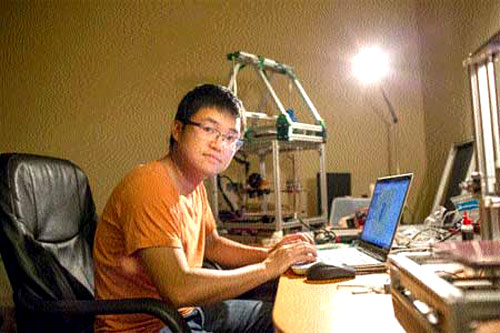

VietNamNet Bridge – Le Truong Son, a Vietnamese physicist with a doctoral degree from Brown University in Rhode Island, USA, dreams of designing a low-cost 3D printer someday.

Son has been working on this project ever since he began studying in the US.

Additive manufacturing (AM) or 3D printing refers to any of the various processes for printing a three-dimensional object. These objects can take almost any shape or geometry and are produced from a 3D model or other electronic data sources. A 3D printer is a type of industrial robot.

Son dreams of producing a 3D printer so reasonably priced that any Vietnamese family can afford to buy it. And he is on track towards making his dream come true.

Fierce competition

Son, who earned his doctoral degree in semiconductor physics from Brown, a private research university, returned to Viet Nam at the end of 2012 after six years of studying abroad.

He brought home a load of components for the first design of his 3D printer in hopes of mass-producing it someday.

And he met his first challenge after doing research on some domestic manufacturers. He found out that the cost of manufacturing each printer was too high for mass production.

“At that time, the production of a 3D printer costs US$600 to 700 each, which was as high as that of the US,” Son revealed.

“The structure and components of the printer are rather complicated, and the cost of its production in Viet Nam remained high,” he added.

Unable to design a printer for mass production, Son continued producing and selling the printer’s chips and boards in the US through eBay, an online shopping website. A childhood friend helped him produce the boards in Viet Nam. He earned more than $10,000 after his first few months of online selling. His first adventure with online selling lasted 15 consecutive months.

However, his sale of 3D printer’s chips and boards on eBay put him in the most difficult situation in the trade market: copycat marketing. After only one week of posting on eBay, the boards that Son designed and made in Viet Nam were copied by a Chinese manufacturer and offered at a lower price.

“I know for sure that the boards of the 3D printer that the Chinese producer offered are from my design because they have the same defects as mine, which I fixed later. Until now, I have no idea how my design got leaked,” Son recalled.

The competition became fiercer. When Son lowered his price from $100 to 80 per board, the Chinese producer offered it at $60. Son finally fixed his price at $70, which he believed was reasonable enough to ensure profit.

“The competition with Chinese products is very strong. It is a challenge that every player has to face when he plays the game,” Son revealed.

“My design of the 3D printer was shaped with the help of Internet users who contributed their ideas and initiatives, so it is not right for me to adopt a patent for the design,” he added. “I welcome others to use my design because my advantage over the copycats is my continuous creativity. The copycats are always left behind by one or two versions.”

Six months earlier, Son stopped selling the boards online. He admitted that the profit was quite good but explained: “I want to devote my time to developing a complete 3D printer. My main goal is to develop and sell a complete 3D printer rather than sell its chips and boards.”

Reasonably priced

Son is aiming to invent a 3D printer worth $300 to 500 each for mass production in the US and Viet Nam. He said the reasonable price and the good quality would make the printer accessible to every family in the world.

“When that happens, any family member may print whatever item he or she wishes to print. The only thing they need is the design of the item,” he said.

Son recalled that he had designed five versions of his 3D printer. “I have a new version every six months. The later versions are always better than the previous ones,” he said. His room is packed with the frames of various versions of his printers.

Son said the idea of designing such a complex printer began with his curiosity over the 3D printer that was placed in his laboratory at Brown University. He immediately observed that the printer enabled users to print whatever they wanted.

In October 2012, after nearly one year of devoting time to the development of a new 3D printer, Son finished his first design.

“I know that I cannot live without that printer,” Son said. After the first version was introduced, he never stopped using his creativity to make a better and more complete 3D printer.

He revealed that he has nearly finished a new version of the printer, and it would be tested soon. Some investors have shown an interest in his design, Son added.

This latest version will be made available on the Amazon and eBay online shopping websites by end-November.

Source : http://english.vietnamnet.vn/